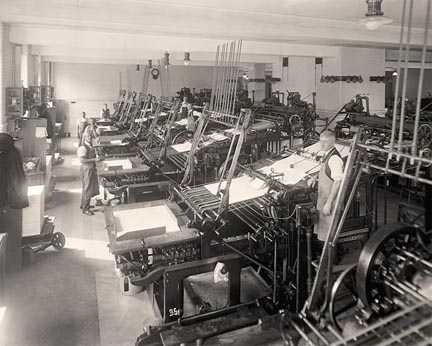

In a CTP chain, documents that must be printed are being reproduced directly on a plate using digital folder. CTP is the abbreviation of “Computer To Plate”. CTP brings out the great digital technology. A desktop publishing application creates images and outputs them in printing plates.

CTP involves the insulation of offset plates using digital folders. The film step is removed. The offset plates are made of different materials generally using aluminum covered by a layer or plates made of polyester or paper for less printing. The plates could be covered by sensitive layer: thermal, silver plate, photopolymer or “without development”.

Considering the laser technique used there are two main types: thermal or visible. The thermal laser is IR type. It uses temperature not a photosensitive reaction. The laser in visible are of different types: violet laser or argon-ion laser. The violet laser is considered cheaper and has a smaller energy consumption.

But we also have to consider that the process is more complicated and is not a very environmentally friendly method. The violet lasers are available as diode lasers. Diode lasers are not at all expensive being produced for DVD products. Violet laser CTP system works only a single laser diode.

The violet laser diode is used due to its durability and features in the DVD technology. The thermal process is one of good quality and durability but has a bigger energy consumption. Thermal CTP are more often chosen for big printing volume. An exchange of the laser diode is you use CTP thermal is necessary after two to four years.

With a thermal process (IR laser) the plates can be used in day-light, the laser has an attack of the polymer of superior layers. The CTP violet laser uses silver plates or photopolymer plates. The silver plates are sensitive and have a smaller energy consumption.

They permit a quick insulation and a good efficient process. The silver plates aren’t compatible with UV ink. The plates made of photopolymer are compatible with UV ink. They are more eco-friendly materials but also present the disadvantage of a lower resolution. The thermal technique uses also the technique without development.

CTP presents several advantages that make it a different, better technique than the traditional method that uses films:

-it has a lower material consumption because it removes films and the chemical process of development

-is a quicker technique because it doesn’t include the plate insulation and film treatment

-it is a more eco-friendly method

-it has a better quality

The main disadvantages are the following:

-it is limited to a digital format

-if an error occurs, the plate must be done again, it can’t be repaired.

There are also advantages to consider of the thermal process without development. It comes with:

-a water lowering,

-removal of films, fixers and developers,

-less waste and products to manage.

In the graphic production there has always been a direction of removing steps that can be removed. Film development is a step that has been removed using the process called Computer To Plate or CTP using a direct insulation over a plate. The plates used in CTP thermal, CTP visible or without development must be of good quality. Considering the new requirements of clients, considering the time and the reduction of costs, CTP comes with great value and quality. It permits to computerize the process of printing.